How to Make a Vacuum Cleaner - Ultimate DIY Explanations

However, for a variety of reasons, you might not own a vacuum or your current model is not quite big enough for the job. If that’s the case, our guide on how to make a vacuum will certainly come in handy, as it allows you to work on your own DIY vacuum with little trouble.

You’ll be surprised at how easy it is to create a simple handheld vacuum with all the accessible materials from home. And of course, with a proper setup, your vacuum can perform relatively well.

Kindly note that our guide will only dive into explaining how the vacuum works and providing you with general instructions on how to make a vacuum cleaner with whatever materials are available to you. So, you are free to be creative with your designs. Just make sure that you read through our article and memorize the general steps to have a good understanding of the procedure.

Explaining how the vacuum works

The vacuum cleaner is a complete airflow system

To begin with, DIYers will need to know how a vacuum actually works, so they can apply the same mechanics to their designs and make sure that the machine can do the job.

On a standard vacuum cleaner, there are three main units, each having its own specific job to contribute to the entire setup. The first and most important part is the motor and the attached fan, which receive power from the battery or from the power outlet to generate suction from inside the vacuum.

The second unit is the attached battery, or the power modules if you are using a direct wired connection to the outlet. Depending on the motor and the design of your DIY vacuum cleaner, the connected power sources will need to differ accordingly. You will also need to install power switches if you wish to turn the machine on and off at will.

Last, but not least, your vacuum cleaner will need a place to store all the collected dirt and debris without affecting the inner parts. So, a dust container with a matching design to the whole machine is always required. Make sure to also install filters to prevent dust from getting into your motors and other parts. The dust container and filters should also be removable so you can easily remove them.

Other than these, you can add different types of cleaning heads and attachments to your DIY vacuum cleaner to improve its performance and usability. A crevice tool will help you clean up in the tight narrow corners. An attached plastic tube will help you reach higher and further. Having an attached handle will also make it easier for you to control the vacuum. The list goes on.

When your vacuum cleaner is running, the machine will generate a powerful flow of air that runs through the entire system, from the opening to the ending vent. This would create suction at the cleaning head so the vacuum can start picking up dirt and debris. All the collected dust will travel through the system of tubes and pipes before entering the container. Here, the filters will prevent the debris from traveling further toward the motor and keep all the dirt inside the vacuum. The rest of the air will continue the flow and escape through the vent while also cooling the motor during the process.

➜ RELATED: Shark IONFlex 2X DuoClean IF251: Flexible Enough for You?

What you will need for your DIY vacuum

After learning about the parts of a vacuum cleaner, you should have a few ideas about which materials you can use for your DIY project. In the following list, I’ll be showing my own take on the available materials for a homemade vacuum cleaner, after having tried a few of them. And since we’re doing a guide on diy vacuum cleaners, it’s best that these items should be available for all households and on a daily basis.

Discover all the tools you need and more

The body

You can use a regular 1.5L plastic water bottle for the body of the vacuum, or a used shampoo bottle could also do the job. Keep in mind that you should only use a container with a cylindrical shape since you’ll be installing the fan inside it. Alternatively, a big chunk of PVC tube is also great for the job. The plastic materials are extremely easy to cut through and can be quite flexible, so you are free to design the body to better match your preferred design.

The tubes

You can use solid PVC pipes and bends for installing the standard cleaning head on your DIY stick vacuum. Simply cut the PVC pipe short to make a standard head for your handheld model. It’s also possible to use flexible pipes for making tubes that resemble a regular canister vacuum. In addition, you are free to combine these materials to create different types of tubing and attachments on your vacuum. Just make sure that they match the suction power on your machine.

The motor and fan

To power up the vacuum cleaner, you will need to install certain motor models onto the machine. For the sake of making a DIY handheld vacuum, a standard 30V motor should be enough for the job. Anything that’s less powerful than this will fall short when it comes to cleaning power. Of course, you can opt for more power, but it will also generate more noise and require more from your power sources.

For the fan, you will need to prepare a metal sheet for making a proprietary fan for the specific motor and your vacuum body. Don’t forget to also get a suitable arbor mandrel that matches the design of your motor and fan.

The filters

Your machine will require filters to keep debris and dust from following the air flow into the motor and out of the vacuum, which will eventually defeat the purposes of vacuuming in the first place. Here, you will typically need two types of filters, one for controlling the majority of the dirt and one for reducing the amount of fine dust in the air.

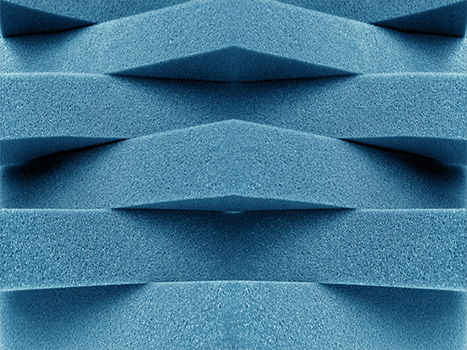

The first layer of filter can be achieved with a simple piece of foam cut to the matching size. Just remember to keep it relatively thick, usually more than 5 centimeters. For the second layer, it would be great if you can get your hands on a HEPA filter. If that’s not possible, a simple cloth filter with matching sizes and designs to your machines will still do fine. Remember, filters are extremely important if you’re looking to make the best vacuum cleaner for pet hair.

The power sources

DIYers will have two options when it comes to the power source on their homemade vacuum cleaner. Here, you can choose to attach the motor directly to a matching battery unit to power up your vacuum on the go. If you can deal with using wire, we would recommend you to opt in for a direct power source since it’s more stable and powerful, although you will need more time to work on setting up the proper modules and regulators. And don’t forget to prepare some electric wirings for your DIY vacuum.

Required tools and other items

Throughout the process, you’ll be using many tools for creating the DIY parts, so it’s important to have them all prepared:

- A hand saw will be needed for cutting and designing the body and other parts of the vacuum.

- A snip will come in handy when designing and refining the metal sheet.

- Certain types of adhesives are required when assembling and constructing the machine.

- A drill is quite useful when designing the vacuum and creating ventilations.

- Markers will help you design and properly adjust the parts.

- An electric welder, while not available for all, is certainly great for connecting the units and wires. But you can also use gel glue to connect them if necessary.

Our step-by-step instructions

With all the tools and materials prepared, together with a well-drawn plan, it’s time for you to start working on your powerful vacuum cleaner. Here, our general step-by-step instructions will guide you through all the important stages on how to make a vacuum cleaner. Make sure to read through them all and add your own take on the different steps, in order to create your true DIY machine with whatever materials are available to you.

Designing and executing the parts

Any regular 1.5L plastic bottle should do the trick

You should start working on the body of the vacuum to design a flexible unit that can be securely assembled and easily taken apart.

For the plastic water or shampoo bottle users, simply cut through the middle of the bottle, from which the bottle diameter is smallest. Then continue to cut on the top half of the resulting pieces, from which the diameter is slightly bigger and can fit perfectly over the smallest diameter.

Remove all the excess pieces and connect the top and bottom halves of the bottles together. They should match perfectly if you do the cutting properly. Now, you can easily take apart the body whenever needed to empty the dirt and put them back together without much trouble.

The head of the bottle can work as the opening for the vacuum. By simply drilling a bunch of holes at the bottom, you can create the exhausting vent for the machine.

If you’re using PVC pipes for making the body of the vacuum instead, it’s important to get two pieces with slightly different diameters so they can be easily attached to each other. Make sure to get the right pipes so they can be assembled and disassembled easily while not being too loose or too tight.

Alternatively, you can get the PVC connectors to connect your two similar pipes together, although it would cost you a little more. Dig small holes on the PVC endcap before attaching it to the bottom of your pipes set up to create the vent. Use the PVC reducer to create the proper opening for the vacuum cleaner.

You can also use PVC pipes for the body and tubes

For the vacuum tubes, you can use solid plastic pipes for making your stick vacuum setup. Or, go for the flexible pipes to make the standard hose that is often featured on the canister or upright machines.

Working on the fan and motor

Next, you should start designing the fan and motor for your vacuum cleaner. Start by using the metal sheet that you’ve prepared and mark the proper size for the fan. Make sure that the fan is small enough to spin comfortably inside the machine without touching the inner walls.

Once you have it drawn out, simply use the snips tool to cut through the metal and create the blades. Grab on each blade and bend it slightly to mimic the shapes of a regular fan. Instead of following the regular installation, you will put the blade in an inverted position on the motor to generate suction. Use the selected arbor mandrel to securely attach the motor to the blade. On the motor, you can add the wire using an electric welder or simply connect the wires with glue.

The entire structure will need to be attached to the bottom of the plastic bottle or the PVC lid, depending on your choice of materials. Make sure to use a lot of glue to keep everything secured. From my experiences, silicone glue is the best for the job since it is powerful, resilient, and almost non-destructible. If you use a lot of it, the glue will also form a solid foundation once it’s dried, so the motor can be more secure.

Use a small engine motor for the job

At this stage, if you are using a plastic bottle, I highly recommend you cut through the near end to separate the bottom part from the body. Do the same thing with the top of the vacuum unit so you can take off the bottom part and the motor attached to it. This is really handy when first installing the motor and whenever you need to clean the dust container and filters.

➜ RELATED: How To Use Vacuum Cleaner - Tips And Techniques To Vacuum Your Floor Properly

Setting up the power sources

For the power sources, you can simply prepare your rechargeable batteries setup with proper voltage and power for the vacuum, then attach the unit to the wires to start running the vacuum cleaner.

On the other hand, if you’re interested in running with direct power from the outlet, then there will be more to be done. Here, you will need to create a power regulator unit, using modules and voltage regulators. Attach the wires to the unit then connect the unit to any available power source. This will allow the machine to run at a proper electric current and voltage for its particular motor.

Also, you can choose to add a switch to the wires so the machine will run whenever you want it to. Simply choose any part of the wires and cut one of them in half. Attach the two ends of the wire to the respective opening of the power switch. Now, you can simply turn your vacuum on and off with the switch.

Designing and adding the filters

With most of the job finished, you will need to work on tailoring the filters to match the inside of the machine. For the foam filter, simply use any piece of foam with the proper thickness and use scissors or a razor blade to cut it into a cylindrical form. Make sure to keep the profile relatively big so the filter can fit better inside your vacuum container.

Cut foam to the right size to create the matching filter

Once that’s ready, you’ll start by inserting and gluing the cloth filter on the inside of the vacuum. Place it in front of and without touching the fan before adding glue to solidify the unit. Wait patiently for the glue to dry and continue to check for any spots that need more glue. Continue to work on adjusting the cloth filter until you are satisfied. Then proceed to add the foam filter on top of the cloth filter. Fix it with some kind of glue, or leave the foam filter as it is if it’s already secured.

Assembling the vacuum machine

With everything ready, you can proceed to refine the parts and start assembling your vacuum machine. Grind away the sharp edges on the fan blades so they won’t damage the inner walls. Check the glued connections, especially the attached motor, to make sure that they’re all secured and stable. Put the parts together and start testing your vacuum to see how it works.

Feel free to go through our how to make vacuum instructions once again after you finish making your DIY vacuum to review the machine and check for potential improvements.

A few useful FAQs

And if you are still having concerns about how to make a vacuum and how you can use your DIY handheld vacuum in general, then the following FAQs will certainly come in handy.

How to clean carpets

The vacuum should work great on collecting dirt on multiple surfaces. However, without the proper cleaning head, you will find it quite difficult to get into the thicker layer in your carpets. So, if you’re trying to use the DIY vacuum for cleaning carpets, it’s suggested that you brush up the surfaces a little bit to loosen the dirt. Also, if your pets have recently peed on the carpet, you don’t want to use your vacuum on it, unless you want the entire machine to become smelly and you have to deal with the odors. Instead, read the how to get urine smell out of carpet article on our website to discover proper ways to deal with the odors.

How often should I vacuum?

With the simple design, decent performance, and easy maintenance, you can use the DIY vacuum cleaner for most of your vacuuming needs. However, different tasks will require you to perform the cleaning at different frequencies. Feel free to check out our posts on How Often Should You Vacuum to learn more about this.

Conclusion

If you don’t have a vacuum cleaner or your current machine is too big for dedicated cleaning tasks, then our useful guide on how to make a vacuum will certainly come in handy. Here, you can learn how to build a vacuum cleaner using easy-to-find materials and follow the detailed steps to come up with your own designs. With just a little bit of hard work and creative thinking, you too can create a cool DIY vacuum that can actually work.

FREQUENTLY ASKED QUESTIONS

- 01. What is the lowest vacuum possible?

-

I assume that the people who asked this question are referring to the power of the vacuum. With the 30V motor that I recommend you use on your DIY setup, you should be getting around 300W when it comes to vacuuming performance, which is quite standard for handheld models. You can still go with a lower power source like a 12V motor, but it won’t perform as good as the standard unit. The choice is yours.

- 02. What materials are used to make a vacuum cleaner?

-

To make it more relevant, I’ll be answering questions in relation to the post. If you are wondering whether you should use the plastic bottles or the PVC tubes, the answers should depend on your personal preferences and circumstances. Ideally, if you want something that looks more secured and is also more convenient to work with, then the PVC tubes are always the better choice. If you don’t have time to prepare all the different tubes, connectors, and reducers, then the plastic bottle method might be the better choice.

- 03. Can things move in a vacuum?

-

I can’t even think of who would question this, but the short answer is no. Besides the fan and the air, nothing should be moving inside your DIY vacuum, unless you want stuff to start damaging the inside. That is why we have filters installed to prevent large debris and dirt from getting into the machine. So, the next time you use your DIY machine, it’s best to disassemble it and check for any unwanted materials.